Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: HYS-125

Brand: QIUXUE

Place Of Origin: China

Types Of: Synthetic Fibers

RELATED VISCOSITY: 2.45/2.8

Color: Black

Packing: 25kgs Or 800kgs Jumbo Bag

Packaging: THE INNER LAYER IS ALUMINUM FOIL AND THE OUTER LAYER IS PP OR KRAFT BAGS.

Productivity: 30000 TONS PER MONTY

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Supply Ability: 350,000 TONS PER YEAR

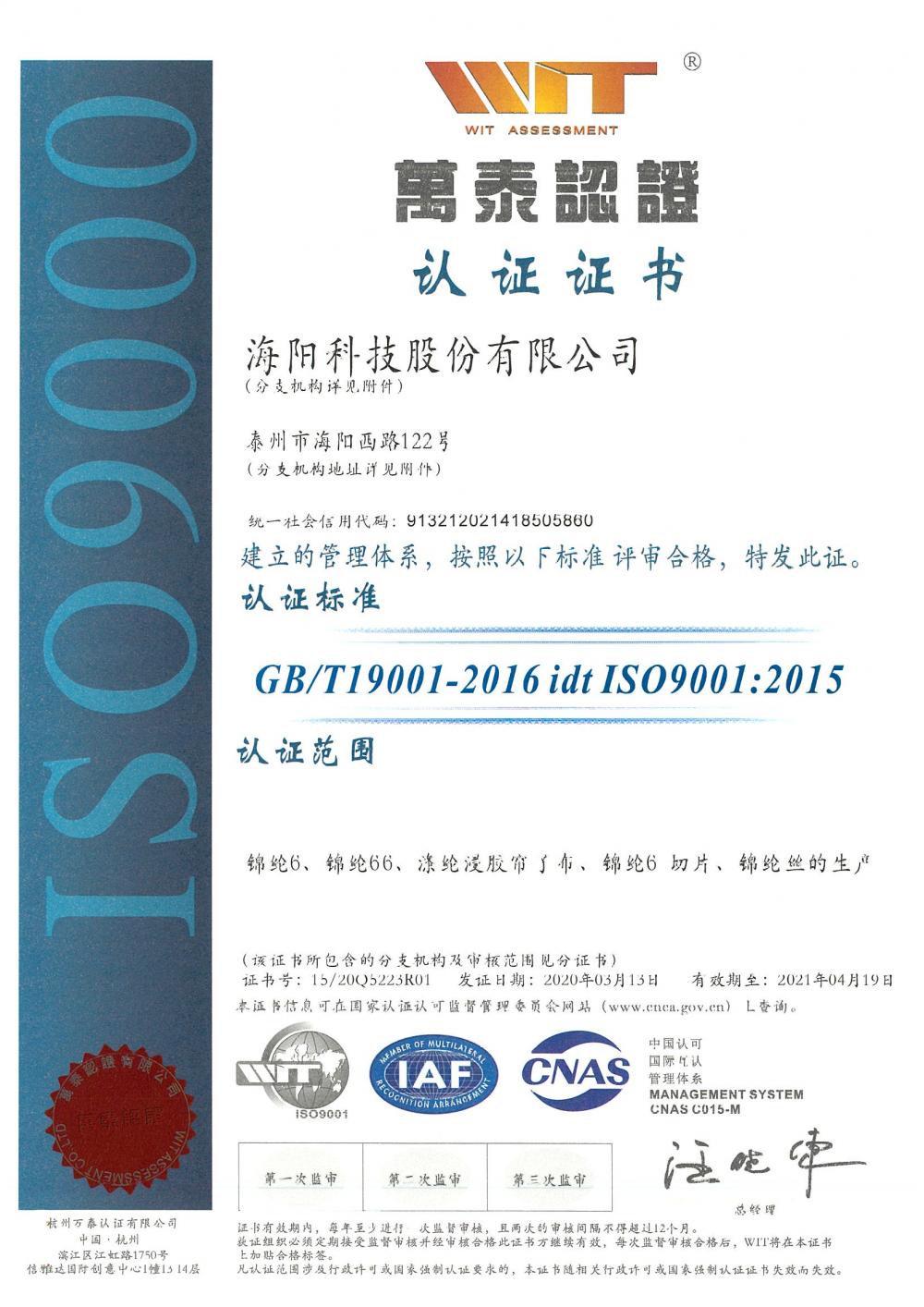

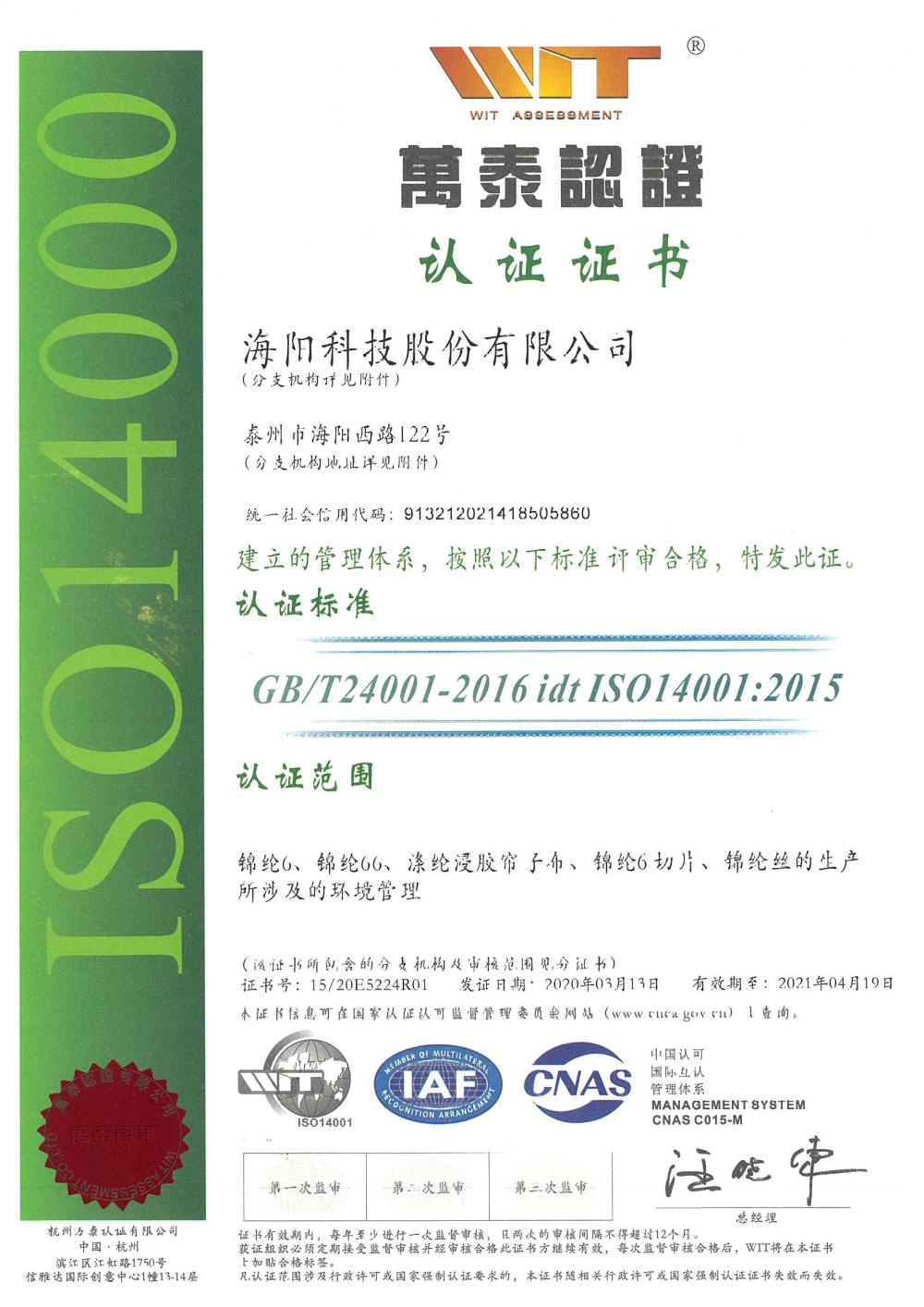

Certificate: ISO9000,ISO14001

HS Code: 390810

Port: SHANGHAI,TAICANG,ZHANGJIAGANG

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

The yarn is made of in-situ POLYAMIDE6 R.V2.45 black resin, which is the world's first large-scale NYLON6 in-situ coloring raw material

Principle: Functional Nylon 6 Yarn dye and melt are fully mixed in the polymerization process, and dyed yarn is obtained by spinning.

Advantages: no dyeing after weaving, no dyeing sewage discharge, water saving and energy saving, green and environmental protection, in-situ polymerization of true green yarns, high color fastness, uniform color, no color difference between batches to improve post-dyeing efficiency process.

feature

1. T 1. Greener

Yarn use Pa6 black flakes are polymerized in-situ, and they turn black after polymerization, which avoids energy consumption and environmental pollution during the production of masterbatches.

Reduce the harm of dust to employees during the production of masterbatches

2. The equipment is not changed

Since Pa6 Black Chips are black, they can be directly used to reduce investment in equipment such as main injectors. At the same time, it is also the world's first mass-produced in-situ polymerized black section.

3. Components have a longer service life

By using nanoscale pigments, the In-Situ Pa6 Black Chips enable longer component cycle times and higher yields. Generally, the masterbatch spinning assembly needs to be replaced in 15-25 days, the in-situ polymerization black segment can be used for 40-60 days, and the assembly pressure is basically unchanged.

2. 4. Little damage to false twist friction discs, no damage to knitting needles

The pigment is nano-scale, and the dispersion is finer, more uniform, and the surface is smoother. Reduce friction disc damage and needle wear, reduce crochet phenomenon

3. 5. The color is more uniform, no color difference, and the color fastness is higher

It avoids the color difference and low color fastness caused by uneven addition of color masterbatch in the spinning process, so that the color uniformity is better, and the color is bluish. Color fastness can reach grade 5 (gray card), light fastness, acid and alkali resistance, washing fastness can reach grade 4.5 (gray card)

6. Anti-static

Its antistatic performance is better than that of white yarn dyeing

The world-renowned Haishun Group has been using the following specifications, and other varieties are getting better results in trial spinning

|

产品类别Description | 锦纶 6 切片 Nylon6 chips | 牌号 Grade | HYS-125 | 锦纶 6-原位聚合黑切片 IN-SITU NYLON6 BLACK CHIPS | |||

| 检测标准Test standards |

ISO、FZ/T、ASTM、DIN | ||||||

| 检测项目 Properties | 单位 Unit |

|

规格范围 Specification range | 检测结果 Values | 检测方法 Test method | ||

| 相对粘度 RV 96% H2SO4 |

|

|

2.45±0.03 |

2.46 |

FZ/T 51004 | ||

| 水分含量 Moisture content |

% |

|

≤0.06 |

0.026 |

ISO 15512 | ||

| 萃取物含量 Extract content |

% |

|

≤0.6 |

0.16 |

FZ/T 51004 | ||

| 黑度 Blackness |

|

| 深黑 Atrous |

| |||

Product Categories : Nylon 6 Chips > Colored Nylon 6 Chips

BRIGHT NYLON6 CHIPS IS WIDELY USED IN ENGINEERING PLASTIC AND TEXTILE GRADE.ITS VISCOSITY IS FROM 2.0 TO 3.45.ITS ADVANTAGE IS GOOD APPEARANCE, GOOD SPINNING ABILITY,HIGH STRENGTH AND HIGH DYEING PERFORMANCE.WE PRODUCE THE PRODUCT VIA HIGH HIGH-END LIQUID MATERIALS WHICH IS IMPORTED FROM USA, JAPAN, THE NETHERLANDS, ETC., WITH VK CONTINUOUS POLYMERIZATION, UNDERWATER GRANULATION, CONTINUOUS AIRFLOW DRYING, DCS CONTROL AND OTHER TECHNOLOGIES.THE AMINO TERMINAL GROUP, MONOMER CONTENT AND OTHER SPECIFICATION ARE BETTER.

WHY CHOOSE US:

1. WE ESTABLISH IN 1970,WITH 50 YEARS’ EXPERINCE IN PA6 FIELD.

2. 1600 EMPLOYEE

3. OUR SALES AMOUNT IN 2020 IS MORE THAN USD400.00 MILLION

4. WE HAVE ISO9000,ISO14001,IATF16949,REACH,ROHS,TFS CERTRIFICATE.

SPECIFICATION:

|

NO |

ITEM |

NORM |

DATA |

|

1 |

VISCOSITY |

Q/321200WLB001—2019 |

M±0.04 |

|

2 |

MONOMER CONTENT(% ) |

Q/321200WLB001—2019 |

≤0.6 |

|

3 |

MOSITURE CONTENT(% ) |

Q/321200WLB001—2019 |

≤0.06 |

|

4 |

AMINE END GROUPS(Meg/kg) |

Q/321200WLB001—2019 |

40±3 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.